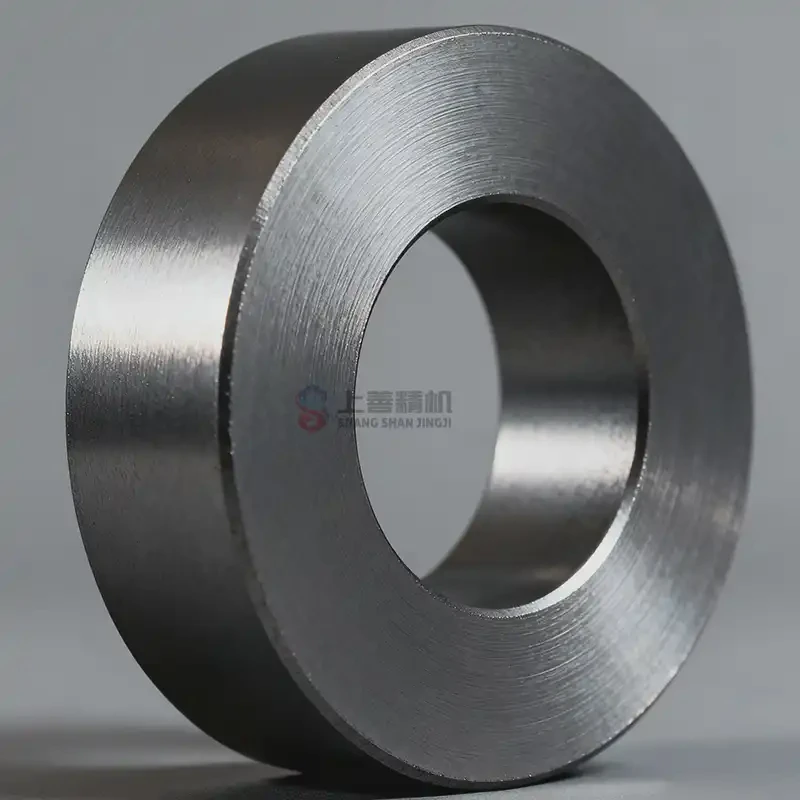

Graphite Rings: An In-depth Analysis of the Core Component in Industrial Sealing

As a core component in the industrial sealing field, graphite rings have become the preferred sealing solution for high-temperature, high-pressure, and strong corrosion conditions due to their unique material characteristics. This ring-shaped material composed of carbon elements demonstrates excellent performance while also having objective limitations. An in-depth analysis of its technical characteristics and application boundaries is of significant value for improving the reliability of modern industrial equipment.

I. Material Characteristics: Coexistence of Advantages and Limitations

(1) Core Performance Advantages

The self-lubricating property of graphite rings stems from their layered crystal structure, with a friction coefficient as low as 0.05 - 0.1. At a linear speed of 30 m/s, they can form a stable lubricating film without additional lubrication. Measured data from a chemical enterprise's reactor shows that after adopting graphite rings, the equipment operation cycle extended from 3 months to 18 months, with maintenance costs reduced by 76%. Their thermal stability is equally outstanding, with a linear expansion coefficient stable at 2.5×10⁻⁶/°C in the temperature range of -200°C to 850°C. An aerospace enterprise developed ultra-low temperature graphite rings that maintain sealing performance even in -196°C liquid nitrogen conditions.

In terms of chemical stability, graphite rings exhibit excellent resistance to strong acid and alkali environments with pH 0 - 14. On a pharmaceutical enterprise's cephalosporin antibiotic production line, graphite seals operated continuously for 2 years without corrosion leakage, whereas traditional fluoroelastomer seals had an average lifespan of only 3 months. The thermal management advantage is reflected in a thermal conductivity of 150 - 200 W/(m·K). After adopting graphite rings in new energy vehicle battery modules, temperature uniformity improved by 40%, and fast charging efficiency increased by 15%.

(2) Objective Performance Limitations

Elastic recovery capability has a critical threshold; when system pressure exceeds 25 MPa, the elastic deformation compensation effect of graphite rings significantly diminishes. Measured data from a petroleum refining project shows that under 40 MPa high-pressure differential conditions, the leakage rate of traditional graphite rings rises to 0.3%, while improved products with gradient density design can control the leakage rate within 0.02%.

Material brittleness is another technical bottleneck, as the impact strength of graphite rings is only 1/5 that of carbon steel. In semiconductor manufacturing equipment, high-purity graphite rings (fixed carbon ≥99.999%) require nanocrystallization treatment to increase toughness by 3 times when applied in wafer transfer systems, to meet micro-vibration conditions under Class 1 cleanliness requirements. Although thermal conductivity is superior to most non-metallic materials, the 150 - 200 W/(m·K) thermal conductivity is still lower than that of metallic copper at 400 W/(m·K), requiring use with metal heat sinks in superconducting magnet cooling systems.

II. Technical Adaptation in Typical Application Scenarios

(1) Mechanical Sealing Field

In centrifugal compressors, the friction pair composed of graphite rings and tungsten carbide rotating rings achieves sealing precision of 5 μm, improving compressor efficiency by 8%. Data from a petrochemical enterprise's hydrogenation unit shows that after adopting three-segment self-compensating graphite rings, seal life extended from 5,000 hours to 20,000 hours, saving 1.2 million yuan annually in seal replacement costs.

In valve sealing, gradient density graphite valve seats perform excellently under high-pressure differential (ΔP≥40 MPa) conditions. A deep-sea platform project shows that after adopting silicon carbide-coated graphite rings, the leakage rate of subsea pipeline valves decreased from the industry average of 0.5% to 0.01%, saving 850,000 yuan per valve annually in operation and maintenance costs.

(2) Emerging Technology Fields

In the nuclear energy field, boron carbide-impregnated graphite rings achieve a neutron absorption efficiency of 92%, making them the preferred sealing material for nuclear reactor control rods. Measurements from a nuclear power project indicate that this material has a performance degradation rate of less than 5% over a 10-year service period, far superior to the 30% degradation rate of traditional borated steel.

In the biomedical field, surface-modified graphite rings demonstrate unique value in drug crystallization processes. Application data from a production line of a renowned pharmaceutical enterprise shows that by controlling crystal nucleation rates, product purity increased from 99.5% to 99.95%, with a single batch output value increasing by 3 million yuan.

III. Deep Penetration in Industry Applications

(1) Traditional Industrial Fields

In the petroleum and chemical industry, graphite rings hold a 65% market share in pipeline sealing. A refining project shows that after adopting epoxy resin-impregnated carbon-graphite rings, the seal failure cycle of high-temperature cracking units extended from 180 days to 900 days, reducing unplanned shutdown losses by 20 million yuan annually.

In the power industry, the application proportion of graphite rings in supercritical units reaches 80%. Measurements from a large power plant show that after adopting graphite seals in steam turbine shaft sealing systems, the vacuum leakage rate decreased from 0.3 kPa/min to 0.05 kPa/min, and unit thermal efficiency improved by 1.2 percentage points.

(2) Strategic Emerging Industries

In the aerospace field, the penetration rate of graphite rings in rocket engine fuel systems reaches 75%. Testing of a certain model engine by a space agency shows that after adopting nanocrystalline graphite rings, the thrust chamber seal life extended from 5 starts to 20 starts, reducing single launch costs by 40%.

In semiconductor manufacturing, high-purity graphite rings hold a 90% market share in wafer transfer system sealing. Application data from a production line of a semiconductor manufacturing enterprise shows that through particle control technology, product yield increased from 85% to 92%, increasing annual output value by 230 million yuan.

IV. Technological Evolution and Industry Trends

Current graphite ring technology is developing in three main directions: In material compounding, carbon fiber-reinforced graphite rings achieve a bending strength of 150 MPa and have been applied in deep-sea exploration equipment; in intelligent manufacturing, AI quality inspection systems have reduced product defect rates from 0.3% to 0.02%; in customized services, digital twin technology can predict seal replacement cycles 6 months in advance.

According to international mechanical industry statistics, the global graphite ring market reached a certain scale in 2024 (specific data not detailed), with a compound annual growth rate of 12.7%. Driven by green energy strategies, demand for graphite seals in hydrogen energy storage and transportation is growing by 25% annually, and by 18% in geothermal development, indicating that this traditional material is opening new growth avenues in the new energy sector.

From deep sea to space, from traditional industries to cutting-edge technology, the technological evolution of graphite rings reflects the innovation trajectory of materials science. The dual nature of their performance is like a double-edged sword, requiring engineers to avoid limitations in application while driving material scientists to continuously break through technical boundaries. In the Industry 4.0 era, graphite rings are reshaping the value dimensions of sealing technology with new forms of intelligence, composability, and customization.